The answer is to use the Sykam manual preparative HPLC syringe injection valve with injection volumes up to 10 ml or larger with customized sample loops.

Of course, with preparative HPLC systems you can use dedicated autosamplers or additional HPLC sample pumps to inject larger sample volumes into the high-pressure flow path but what if only a single or a few samples needs to be injected to get your target molecule purified?

Just adding a manual preparative injection valve to virtually any preparative HPLC system allows you to quickly inject any volume up to the maximum sample loop volume that you have mounted on the injection valve. The only thing you need is a simple plastic dosing syringe to introduce the sample into the sample loop.

For this purpose Sykam has the S 6021 stainless steel 2-position valve with a needle injection port on the front side, or the S 6121 valve as bio-inert PEEK version. Both valves have a built-in position sensor for starting data acquisition precisely at the point of injection. A choice of rotor seal materials is available if fluid contact materials are of any concern for the application.

Apart from the manual injection valves Sykam offers a complete range of analytical and preparative HPLC switching valves and automated valve drives that allow you to realize virtually any chromatographic flow path.

See below how a simple isocratic or low-pressure gradient pump and a UV detector can be converted to an advanced column switching, multiple manual and semi-automatic sampling system and fraction collection system by just adding a few switching valves.

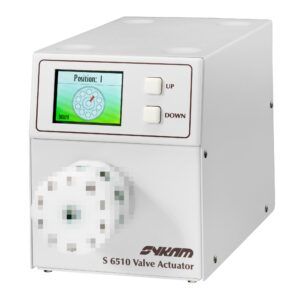

Any of the Sykam HPLC switching valves can be controlled manually, or motor driven by the Sykam S 6510 single valve actuator or the S 6515 multiple valve actuator and controlled by analog contact closure input signals or by RS-232 serial interface control. Besides software control as part of Sykam HPLC systems, the RS-232 serial interface communication protocol facilitates easy integration with other control systems.